Sofa Leather, Leather Machinery Price, Leather Machine, Automatic Shoe Making Machine, Leather Tanning Machinery, Leather Line Machinery a Full Production Line

Usage: This production line is able to make different types of needle punch fabrics, such as Geotextile, geomembrane fab;

Basic Info.

| Model NO. | HR |

| Customized | Customized |

| Condition | New |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Warranty | Offer Free Spare Parts and Service Within 12 Month |

| Needle Density | 4000-6000s/M |

| Total Power | 9-30kw |

| Working Experience | 32 Years′ Experience |

| Machine Painting Color | Be Made According to Your Need |

| Delivery Time | 25 Days |

| Price | Lowest Reasonable Offers in The Market |

| Voltage | 380V/50Hz 3phase Can Be Customized |

| Item | Automatic Shoe Making Machine , |

| Transport Package | Standard Package, Be Made According Cutomer Need |

| Specification | Width 2000-7200mm |

| Trademark | HUARUI |

| Origin | Qingdao |

| HS Code | 84451190 |

| Production Capacity | 100 Sets / Month |

Product Description

Usage:

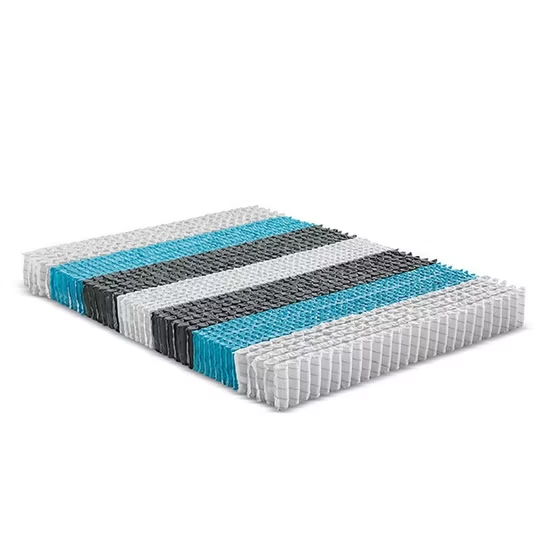

This production line is able to make different types of needle punch fabrics, such as Geotextile, geomembrane fabric, automobile interlining felt, synthetic leather substrate fabric, colorful fabrics, wool felt, carpet, mopper fabric, bentonite felts,and other related fabric.It includes these three main parts: Pre-needle punching machine, main needle-punching machineRaw material: viscose fiber, low melting fiber, polyester, waste cotton fiber and etc.

Technical Data:

| Working width | 2000-4500mm |

| Stroke Frequency | 800-1200s/min |

| Feeding speed | 0.6-6m/min |

Features:

1. Automated and frequency conversion controlled

2. Advanced combined structure enables the excellent stabilization

3. Computerized random distribution of needles

4. Separated lubrication system with air cooling

5. Easy operation and convenient maintenance

You may also like

Send inquiry

Send now